European standard EN 1092-1 – concerning flanges for pipes – establishes the requirements for steel flanges based on their nominal pressure (PN) and dimension (DN).

Moreover, it defines the different kinds of flanges and their sealing surfaces, tolerances, threading and labelling.

What are the differences among the different kinds of flanges?

In this article the different kinds of EN 1092-1 flanges available in our stock will be presented and their peculiar features will be described.

Each classification is labelled with the lettering EN 1092-1 (i. e. the reference standard) followed by a two-digit number indicating the construction of the flange, and a letter which indicates the kind of sealing surface of the flange.

The labelling on the side of all kinds of flanges includes not only the lettering EN 1092-1 TYPE___, but also information concerning PN, DN and casting of the raw material used for the creation of the flange.

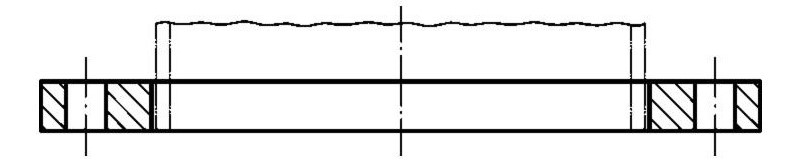

The first and most widespread kind is the EN 1092-1 TYPE 01A flat welding flange. As it was previously explained, the labelling of the flange provides a lot of information: EN 1092-1 indicates the reference standard, TYPE 01 reveals that it is a welding flange and A stands for flat sealing surface. This kind of flanges are used for connecting pipes and they are welded by means of overlap weld. Then, they are joint by means of bolts.

Also the second kind of flanges is a flat welding kind (TYPE 01), but their sealing surfaces are different from the previous one, as they have raised faces (B). EN 1092-1 TYPE 01B raised face flanges host a low relief collar surrounding the central hole of the flange, which proves to be useful for checking the position of the gasket. They are welded by means of overlap weld and they are joint by means of bolts.

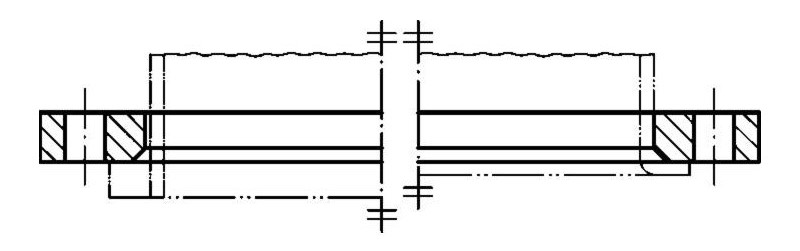

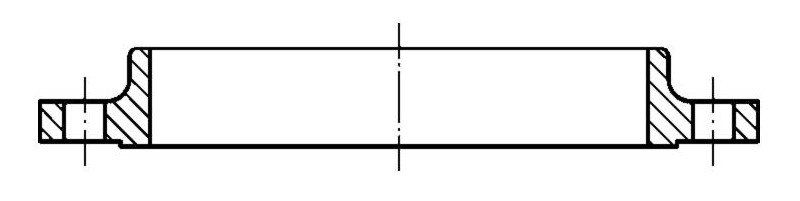

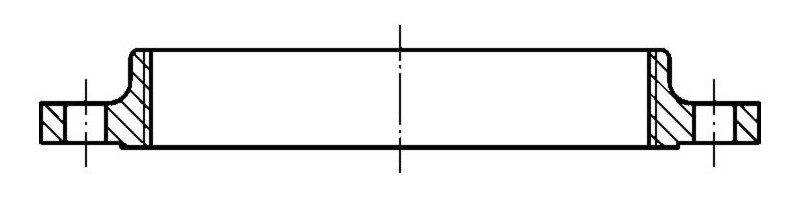

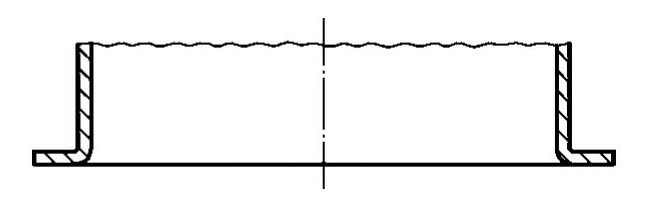

The third kind of flanges available in our catalogue is the EN 1092-1 TYPE 02A lap joint flange. Their labelling can be easily broken down into EN 1092-1 (reference standard) TYPE 02 (lap joint flange) A (flat sealing surface). They are loose flanges to be joint by means of welding collars; bolts are used for their connection.

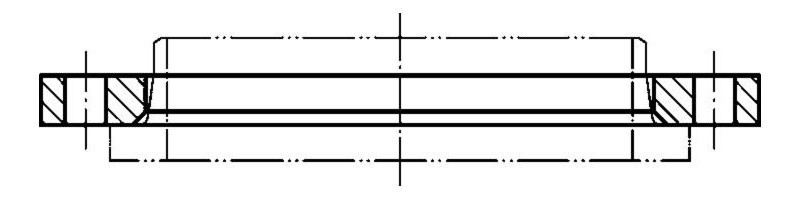

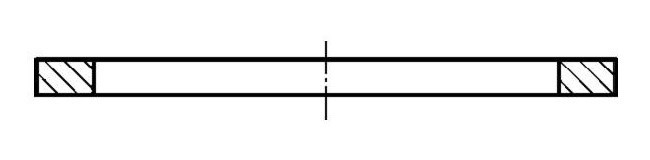

The fourth kind of EN 1092-1 flanges in our stock are flat (A) blind flanges (TYPE 05). EN 1092-1 TYPE 05A blind flanges are used combined with flat welding flanges, raised face flanges or collar as end caps for tubes.

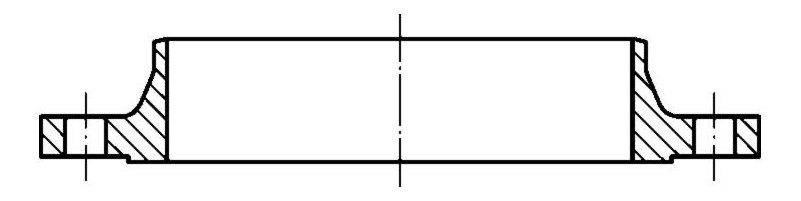

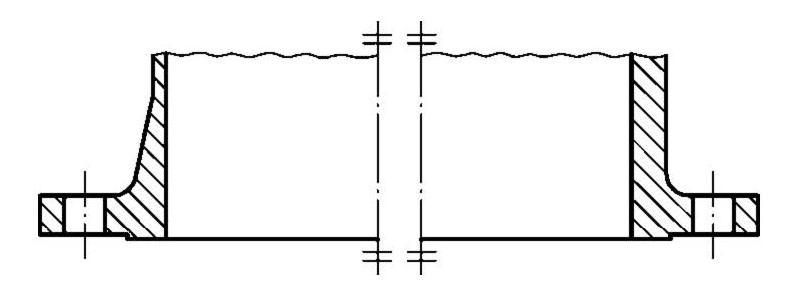

The fifth kind concerns welding neck flanges (TYPE 11) with raised faces (B). The kind of welding used is butt welding.

The sixth kind of EN 1092-1 flanges you can find in our stock identifies threaded flanges (TYPE13) with raised faces (B). They have a female thread for coupling with threaded male ends.

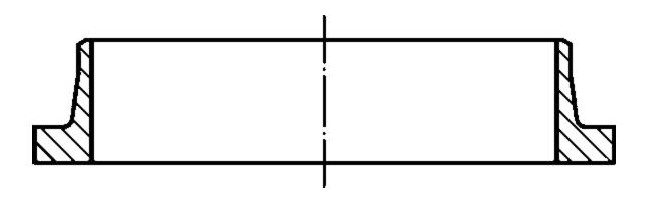

The last kind, EN 1092-1 TYPE 33, establishes the dimensions of welding collars to be used in combination with EN 1092-1 TYPE02A loose flanges or DIN 2642 flanges from pressed stainless steel.

Moreover, Fitting Service can supply, on customer’s request, further EN1092-1 types. See on the table below our full range of EN 1092-1 flanges.

| EN 1092-1: figure 1 (flange types) | ||

|---|---|---|

| Drawn (source: EN 1092-1) | TYPE __ | Full description |

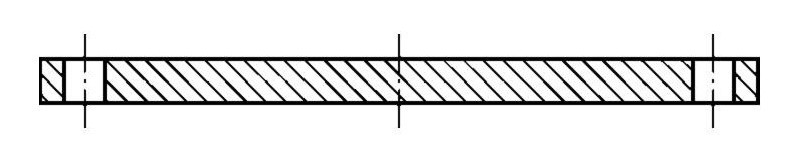

| EN 1092-1 TYPE 01 | Plate flange for welding |

| EN 1092-1 TYPE 02 | Loose plate flange with weld-on plate collar TYPE 32 |

| EN 1092-1 TYPE 02 | Loose plate flange with weld-on plate collar TYPE 33 |

| EN 1092-1 TYPE 04 | Loose plate flange with weld-neck collar TYPE 34 |

| EN 1092-1 TYPE 05 | Blind flange or blank flange |

| EN 1092-1 TYPE 11 | Weld-neck flange |

| EN 1092-1 TYPE 12 | Hubbed slip-on flange for welding |

| EN 1092-1 TYPE 13 | Hubbed threaded flange |

| EN 1092-1 TYPE 21 | LWN – long welding-neck or integral flange |

| EN 1092-1: figure 2 (ancillary components) | ||

|---|---|---|

| Drawn (source: EN 1092-1) | TYPE __ | Full description |

| EN 1092-1 TYPE 32 | Weld-on collar plate |

| EN 1092-1 TYPE 33 | Short collar or lapped pipe end |

| EN 1092-1 TYPE 34 | Weld-neck collar |